RUIAN - An international inserts brand from customers

Home / News / Industry News / ISO Metric Threading Setter Inserts Transform Manufacturing Precision

RUIAN - An international inserts brand from customers

Home / News / Industry News / ISO Metric Threading Setter Inserts Transform Manufacturing Precision

In the ever-evolving world of manufacturing and mechanical engineering, achieving precision and efficiency in threading operations is critical. ISO Metric Threading Setter Inserts have emerged as a vital solution for manufacturers seeking accuracy, repeatability, and longevity in threading applications. As demand for tighter tolerances and higher production throughput increases, ISO Metric Threading Setter Inserts are becoming indispensable in a wide range of industries, from automotive to aerospace and heavy machinery.

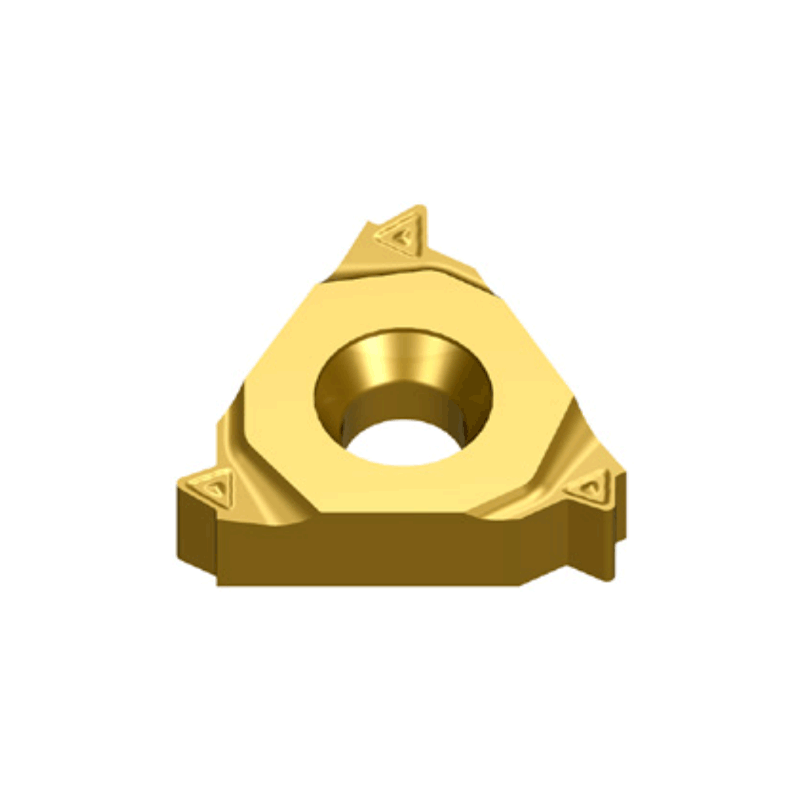

ISO Metric Threading Setter Inserts are precision-ground tools designed to cut or form threads that conform to ISO metric standards — the internationally recognized system for screw threads. These inserts are used in CNC lathes and manual machines to produce consistent internal and external threads, especially in high-volume production environments. The popularity of ISO Metric Threading Setter Inserts has grown exponentially due to their standardization, versatility, and ability to deliver high-quality thread forms under varying operational conditions.

One of the key advantages of ISO Metric Threading Setter Inserts is their compatibility with a broad array of materials, including stainless steel, aluminum, titanium, and even exotic alloys. Tool manufacturers have developed these inserts with specialized coatings — such as TiAlN (Titanium Aluminum Nitride) and CVD (Chemical Vapor Deposition) — to enhance wear resistance and heat dissipation. As a result, ISO Metric Threading Setter Inserts can maintain edge integrity even under high-speed cutting conditions.

Usage scenarios for ISO Metric Threading Setter Inserts are extensive. In the automotive sector, manufacturers rely on these inserts to thread components like engine blocks, transmission housings, and suspension parts. The inserts’ precision ensures that fasteners fit goodly, reducing the risk of component failure due to thread mismatches. In aerospace, where safety and accuracy are important, ISO Metric Threading Setter Inserts are employed in the machining of turbine components, fuselage connectors, and landing gear assemblies. The reliability of these inserts helps meet the stringent quality standards demanded by regulatory bodies and OEMs.

In the oil and gas industry, ISO Metric Threading Setter Inserts play a critical role in producing threaded connections for drilling equipment and pipeline couplings. Given the harsh environments in which these components operate, threading must be flawless to prevent leaks or mechanical failure. Here, the inserts' ability to maintain thread geometry over long production runs proves especially valuable.

Heavy equipment manufacturers also benefit from ISO Metric Threading Setter Inserts. These companies often work with large-scale components made from hardened steels or cast irons, which can be challenging to thread. The toughness and optimized chip-breaking geometry of ISO Metric Threading Setter Inserts allow machinists to maintain productivity without compromising tool life or part quality.

With the rise of Industry 4.0 and smart manufacturing, ISO Metric Threading Setter Inserts have adapted to digital integration. Modern CNC tooling systems now include sensors and data collection capabilities that monitor insert wear, cutting temperature, and force. This data helps manufacturers schedule predictive maintenance and avoid costly downtime. Many insert suppliers now provide digital twin models and CAD files for ISO Metric Threading Setter Inserts, allowing engineers to simulate threading operations before machining begins.

Another emerging trend is the use of ISO Metric Threading Setter Inserts in additive manufacturing post-processing. As 3D-printed metal parts become more prevalent, particularly in custom or low-volume production, precision threading is often required after printing. ISO Metric Threading Setter Inserts provide an effective solution for finishing threads in these near-net-shape components, bridging the gap between additive and subtractive processes.

ISO Metric Threading Setter Inserts are also advancements in sustainability. By extending tool life and reducing scrap rates, these inserts help lower the environmental impact of machining operations. Some manufacturers are even exploring recyclable substrates and eco-friendly coating processes to further align with green manufacturing goals.

Despite their numerous benefits, the selection of the correct ISO Metric Threading Setter Insert remains crucial. Factors such as pitch, helix angle, thread profile, and workpiece material must all be considered. resulting inoling providers now offer AI-powered selection tools and expert support services to guide users in choosing the good insert for their application.

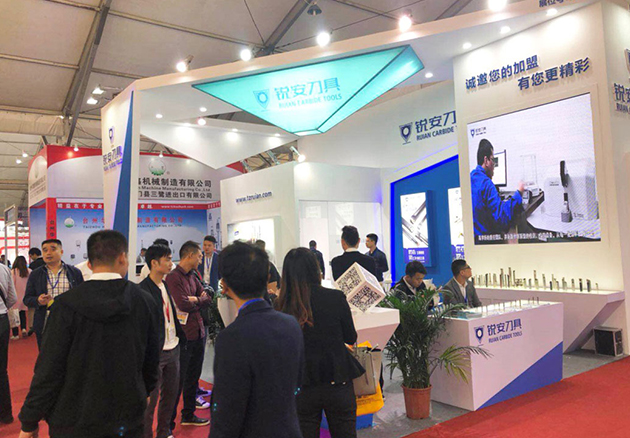

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China