RUIAN - An international inserts brand from customers

Home / News / Industry News / Precision and Efficiency: The Evolution of CNC Cutting Router Bits Tool Sets

RUIAN - An international inserts brand from customers

Home / News / Industry News / Precision and Efficiency: The Evolution of CNC Cutting Router Bits Tool Sets

In the realm of modern manufacturing and woodworking, CNC cutting router bits tool sets have emerged as indispensable equipment, revolutionizing the precision and efficiency with which intricate designs and cuts are executed. These tool sets, equipped with a variety of specialized bits tailored for different materials and cutting tasks, play a pivotal role in transforming raw materials into finely crafted components used across industries such as furniture manufacturing, cabinetry, signage production, and beyond. As technology advances and demands for intricate designs grow, CNC cutting router bits tool sets continue to evolve, offering enhanced capabilities, versatility, and reliability to meet the needs of diverse applications.

A CNC cutting router bits tool set encompasses a diverse array of cutting tools designed to handle various materials with precision and efficiency. From solid woods like oak and maple to composite materials, plastics, and metals, these tool sets are equipped with specialized router bits capable of achieving clean cuts, intricate profiles, and precise contours. Each router bit within the set is engineered with specific geometries, coatings, and cutting edges optimized for different materials and cutting speeds, ensuring performance and minimal wear during operation.

The versatility of CNC cutting router bits tool sets extends to their ability to execute a wide range of cutting operations, including edge profiling, dado cutting, engraving, and carving intricate designs. This flexibility allows manufacturers and craftsmen to explore creative possibilities and meet diverse customer demands, whether producing custom furniture pieces, decorative moldings, or high-precision components for industrial applications.

At the heart of CNC cutting router bits tool sets lies their precision engineering and cutting accuracy, which are critical for achieving consistent and high-quality results. Advanced manufacturing techniques and materials, such as carbide-tipped blades and diamond-coated bits, ensure durability and sharpness over extended periods of use. This precision is further enhanced by computer-controlled routers that execute programmed designs with micron-level accuracy, translating digital designs into flawless physical manifestations with minimal margin for error.

Moreover, CNC cutting router bits tool sets incorporate advanced features such as variable flute geometries, chip-clearance designs, and anti-kickback mechanisms that optimize cutting performance and safety. These features mitigate common challenges such as chip buildup, material tear-out, and vibration, ensuring smooth cutting operations and preserving the integrity of the workpiece surface.

The adoption of CNC cutting router bits tool sets enhances productivity and operational efficiency in manufacturing environments. These tool sets enable automated machining processes that minimize manual intervention and reduce production time, allowing manufacturers to achieve higher output volumes without sacrificing quality. Automated tool changing systems integrated into CNC routers facilitate seamless transitions between different router bits within the tool set, enabling uninterrupted workflow and machine uptime.

Furthermore, CNC cutting router bits tool sets support just-in-time manufacturing practices by enabling rapid prototyping and on-demand production capabilities. Manufacturers can efficiently respond to customer orders and design modifications by quickly reprogramming CNC routers to accommodate new cutting requirements, thereby reducing times and improving customer satisfaction.

The evolution of CNC cutting router bits tool sets is driven by continuous technological advancements and innovative design solutions aimed at expanding capabilities and improving user experience. Integrated sensor technology and real-time monitoring systems provide operators with valuable insights into cutting parameters such as tool wear, spindle speed, and feed rates, allowing for proactive maintenance and optimization of cutting processes. Additionally, intuitive software interfaces and CAD/CAM compatibility enable seamless integration with digital design workflows, empowering designers and engineers to create intricate and complex designs that push the boundaries of creativity and craftsmanship.

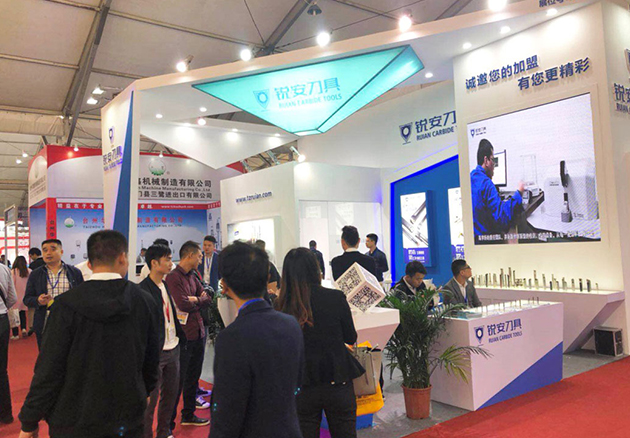

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China