RUIAN - An international inserts brand from customers

Home / News / Industry News / Changes in Negative General Cast Iron Semi-Finishing Turning Inserts Drive Machining Efficiency

RUIAN - An international inserts brand from customers

Home / News / Industry News / Changes in Negative General Cast Iron Semi-Finishing Turning Inserts Drive Machining Efficiency

In a significant development for the metalworking and machining sectors, Negative General Cast Iron Semi-Finishing Turning Inserts are emerging as a key solution for manufacturers seeking improved durability, precision, and performance in the semi-finishing of cast iron components. As demand for more efficient and cost-effective tooling solutions grows, industry innovators are turning their attention to the enhanced properties of these innovative inserts.

Negative General Cast Iron Semi-Finishing Turning Inserts are specifically engineered to tackle the unique challenges associated with machining cast iron materials. Known for their abrasive nature and inconsistent hardness, cast iron workpieces require robust and highly wear-resistant tools. These inserts are designed with negative rake angles and optimized geometries that allow for stronger cutting edges, reduced insert failure, and longer tool life during semi-finishing operations.

Over the past year, several global cutting tool manufacturers have reported increased adoption of Negative General Cast Iron Semi-Finishing Turning Inserts across automotive, heavy equipment, and industrial component sectors. According to a recent report by Global Tooling Insights, market demand for cast iron machining tools has risen by 15% year-over-year, with negative-style inserts making up a substantial portion of the growth.

One of the key benefits of Negative General Cast Iron Semi-Finishing Turning Inserts is their enhanced chip control and heat dissipation. Semi-finishing requires high material removal rates while maintaining surface integrity for final finishing passes. These inserts are designed with specialized chipbreaker geometries that manage cutting forces more efficiently, reduce heat accumulation, and minimize built-up edge—ensuring a consistent surface finish and dimensional accuracy.

Tooling specialists at companies such as Sandvik Coromant, Kennametal, and Seco Tools have all emphasized the role of Negative General Cast Iron Semi-Finishing Turning Inserts in achieving process stability. In a recent statement, a Sandvik Coromant application engineer noted: “We’ve seen significant improvements in throughput and surface quality when using negative rake inserts for semi-finishing cast iron parts. The toughness of these inserts, especially in high-volume production, has proven invaluable.”

Moreover, advancements in insert coating technologies have contributed to the rising performance of Negative General Cast Iron Semi-Finishing Turning Inserts. Modern coatings such as CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition) improve wear resistance and thermal stability. This combination of substrate strength and advanced coatings allows machinists to run at higher cutting speeds with fewer insert changes, reducing machine downtime and increasing productivity.

From a cost perspective, the use of Negative General Cast Iron Semi-Finishing Turning Inserts offers notable savings. The extended tool life translates directly to lower tooling costs per part. For manufacturers producing large batches of cast iron components, even small improvements in insert life and performance can yield significant economic benefits over time.

Industry experts also point out that Negative General Cast Iron Semi-Finishing Turning Inserts are well-suited for automation. In CNC machining cells and robotic turning systems, insert reliability and predictable wear patterns are essential. These inserts enable unattended operation by ensuring fewer tool-related stoppages, aligning with the broader trend toward smart manufacturing and Industry 4.0.

Several case studies illustrate the transformative impact of Negative General Cast Iron Semi-Finishing Turning Inserts. One automotive supplier reported a 25% increase in output after switching to a new series of negative rake inserts tailored for cast iron. In another example, a machinery parts manufacturer reduced insert consumption by 40% while achieving tighter tolerances and improved surface roughness.

Looking ahead, the development of application-specific variants of Negative General Cast Iron Semi-Finishing Turning Inserts is expected to continue. Manufacturers are experimenting with novel edge preparations, composite coatings, and variable chipbreakers to fine-tune performance for specific grades of gray, ductile, and compacted graphite iron.

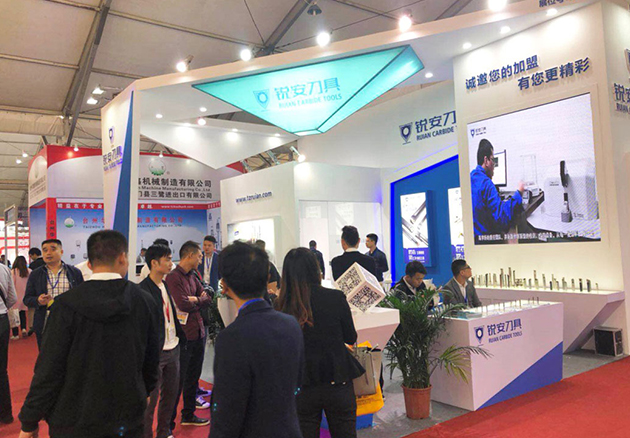

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China