RUIAN - An international inserts brand from customers

Home / News / Industry News / Precision and Productivity Reimagined: Square Shoulder Semi-Finish Milling Inserts Reshape the Machining Industry

RUIAN - An international inserts brand from customers

Home / News / Industry News / Precision and Productivity Reimagined: Square Shoulder Semi-Finish Milling Inserts Reshape the Machining Industry

In the ever-evolving world of metalworking, manufacturers continually seek tools that offer good performance, longer life, and higher precision. One innovation making waves across the machining industry is the Square Shoulder Semi-Finish Milling Insert—a cutting solution that is rapidly gaining traction for its good blend of accuracy, durability, and cost-effectiveness.

Changing Milling Efficiency

Square Shoulder Semi-Finish Milling Inserts are specifically designed to bridge the gap between roughing and finishing operations. Traditionally, achieving a high-quality surface finish required multiple tool changes and precise setups. However, with the new generation of Square Shoulder Semi-Finish Milling Inserts, operators can now streamline processes and reduce cycle times dramatically.

Why Square Shoulder?

The defining characteristic of Square Shoulder Semi-Finish Milling Inserts is their ability to produce true 90-degree shoulders with little secondary machining. This attribute is crucial in industries like aerospace, automotive, and mold and die manufacturing, where tight tolerances and surface integrity are important.

“These inserts are game changers,” says Dr. Laura Mei, Chief Applications Engineer at ToolTech Solutions. “We’ve seen up to 30% reduction in machining time and up to 40% improvement in surface finish when using Square Shoulder Semi-Finish Milling Inserts compared to traditional end mills.”

Material Versatility

One of the key selling points of Square Shoulder Semi-Finish Milling Inserts is their adaptability across a wide range of materials. Whether machining high-tensile steel, cast iron, or exotic alloys like Inconel and titanium, these inserts deliver consistent performance. Manufacturers no longer need to switch tools for different workpiece materials, resulting in reduced downtime and inventory costs.

Kennametal recently showcased a new line of Square Shoulder inserts at IMTS 2024, emphasizing their ability to tackle stainless steels with ease. According to company representatives, their proprietary KCU25 grade with TiAlN coating dramatically improves wear resistance and heat management during long production runs.

Advanced Coatings and Insert Geometry

Modern Square Shoulder Semi-Finish Milling Inserts benefit from advanced coatings such as TiAlN, AlTiN, and PVD/CVD combinations. These coatings not only reduce tool wear but also allow for higher cutting speeds, making the inserts proper for high-production environments.

Additionally, the insert geometry plays a critical role. many new models feature chip breakers and variable rake angles to enhance chip control and reduce cutting forces. This results in better stability, less vibration, and improved dimensional accuracy—all of which are critical in semi-finishing operations.

CNC Integration and Smart Machining

The adoption of Square Shoulder Semi-Finish Milling Inserts has also aligned well with the rise of Industry 4.0. Smart machining centers equipped with real-time monitoring systems are now optimizing tool paths based on insert wear and performance feedback.

“Tool life predictability is greatly enhanced with these inserts,” says Mark Donovan, Senior Process Manager at AeroPrecision Components. “Our CNC systems can detect minute changes in vibration and adjust feeds accordingly, ensuring our Square Shoulder Semi-Finish Milling Inserts are always cutting at their good performance level.”

Environmental and Economic Benefits

The efficiency of Square Shoulder Semi-Finish Milling Inserts also translates into sustainability. Less tool consumption, fewer tool changes, and reduced energy usage all contribute to a smaller carbon footprint. For manufacturers focused on ESG goals, these inserts offer a tangible path to greener production.

Economically, companies are reporting significant ROI within the one quarter of switching to Square Shoulder Semi-Finish Milling Inserts. With longer tool life and fewer rejects due to dimensional errors, even small shops can realize meaningful gains.

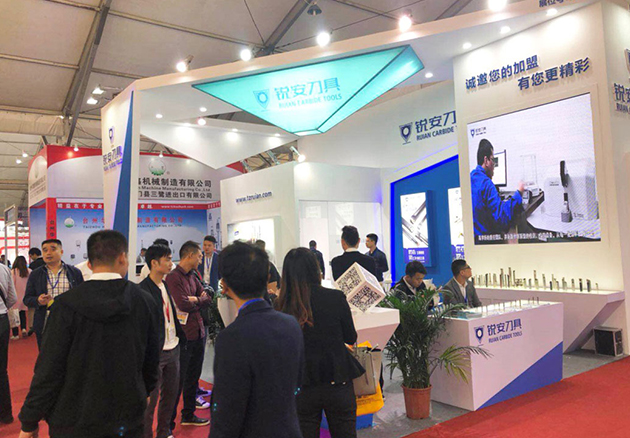

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China