RUIAN - An international inserts brand from customers

Home / News / Industry News / Understanding Negative General Stainless Steel Finishing Turning Inserts: A Key to Precision Machining

RUIAN - An international inserts brand from customers

Home / News / Industry News / Understanding Negative General Stainless Steel Finishing Turning Inserts: A Key to Precision Machining

In the world of modern manufacturing, achieving high precision and good surface finish on stainless steel components is essential. One of the pivotal tools enabling this level of quality is the Negative General Stainless Steel Finishing Turning Inserts. These inserts have changed the finishing turning process, providing machinists and manufacturers with enhanced control, durability, and efficiency.

What Are Negative General Stainless Steel Finishing Turning Inserts?

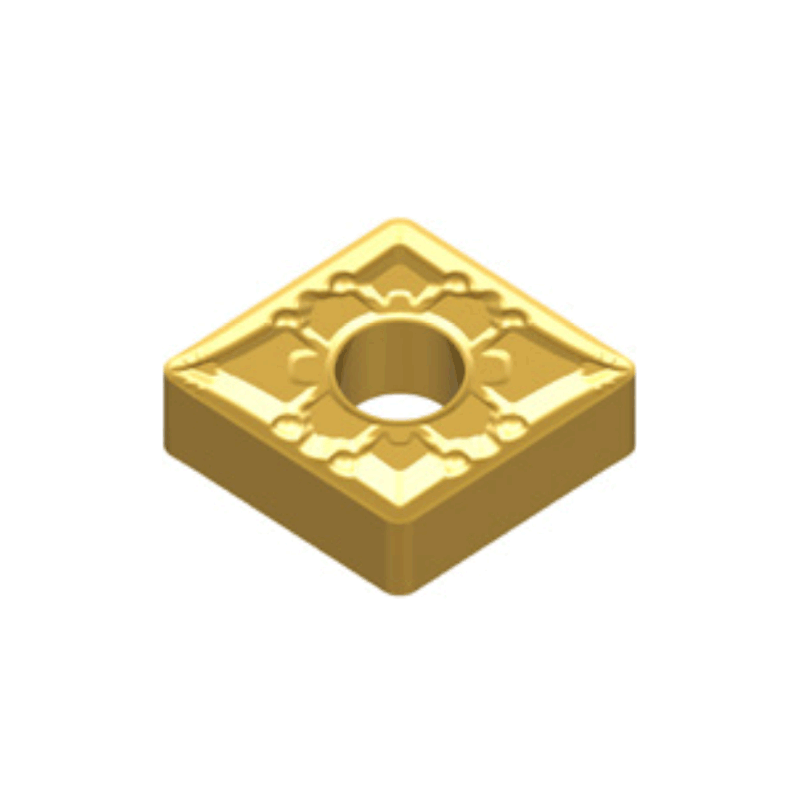

Negative General Stainless Steel Finishing Turning Inserts are specially designed cutting tools used primarily in CNC and conventional turning operations. Their "negative" geometry refers to the shape and edge design that provides a robust cutting edge supported by a negative rake angle. This feature makes them highly suitable for finishing operations on stainless steel—a material known for its toughness, work hardening tendency, and sensitivity to machining conditions.

The Importance of Finishing Turning Inserts in Stainless Steel Machining

Machining stainless steel presents unique challenges due to its high tensile strength and poor thermal conductivity. These factors can result in rapid tool wear, poor surface finishes, and even workpiece damage if the correct inserts are not used. This is where Negative General Stainless Steel Finishing Turning Inserts come into play. They are engineered to withstand the high temperatures and stresses encountered during finishing, maintaining sharpness and dimensional accuracy.

Finishing inserts are generally designed to remove little material, focusing on surface quality and precision dimensional control. The Negative General Stainless Steel Finishing Turning Inserts excel in this role by providing consistent cutting action that reduces vibrations and improves surface smoothness, a critical requirement for high-grade stainless steel components used in industries like aerospace, medical devices, and food processing.

Design Features of Negative General Stainless Steel Finishing Turning Inserts

The design of Negative General Stainless Steel Finishing Turning Inserts typically includes a negative rake angle, which enhances the strength of the cutting edge. This makes the inserts less prone to chipping and breakage compared to positive rake inserts. Additionally, the negative geometry helps in controlling cutting forces, reducing tool deflection during machining.

Moreover, these inserts often come with specially engineered coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Aluminum Oxide (Al2O3). These coatings increase wear resistance and reduce friction, enabling the inserts to cut through tough stainless steel alloys effectively without premature wear.

The edge preparation on these inserts is also tailored to finishing applications. Micro-chamfers or honed edges improve edge strength and contribute to better surface finishes by producing less built-up edge and reducing work hardening on stainless steel surfaces.

Benefits of Using Negative General Stainless Steel Finishing Turning Inserts

good Surface Finish

The primary advantage of using Negative General Stainless Steel Finishing Turning Inserts lies in the good surface finish they provide. The controlled cutting action reduces chatter and vibration, resulting in smooth, precise finishes.

Enhanced Tool Life

Due to their robust geometry and advanced coatings, these inserts last longer under demanding finishing conditions. This translates to reduced downtime and cost savings in tool replacement.

Precision and Stability

The negative rake design offers greater cutting edge support, ensuring dimensional accuracy and repeatability even under heavy finishing cuts.

Versatility

These inserts are compatible with a range of stainless steel grades, from austenitic to martensitic types, making them highly versatile for various manufacturing needs.

Reduced Heat Generation

The coatings and geometry help in dissipating heat more effectively, protecting both the tool and the workpiece from thermal damage.

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China