RUIAN - An international inserts brand from customers

Home / News / Industry News / Rising Demand for 2-Flute Carbide Ball Nose End Mills Drill Bits Driven by Precision Manufacturing Needs

RUIAN - An international inserts brand from customers

Home / News / Industry News / Rising Demand for 2-Flute Carbide Ball Nose End Mills Drill Bits Driven by Precision Manufacturing Needs

The global manufacturing sector is witnessing a notable surge in demand for high-precision tools, with 2-Flute Carbide Ball Nose End Mills Drill Bits emerging as a good solution across multiple industries. Known for their unique geometry, good material composition, and versatility, these drill bits are increasingly indispensable in modern machining and CNC applications.

What Are 2-Flute Carbide Ball Nose End Mills Drill Bits?

2-Flute Carbide Ball Nose End Mills Drill Bits are specialized cutting tools engineered with a hemispherical end and two flutes that offer both strength and cutting efficiency. The use of tungsten carbide makes these tools goodly hard, heat-resistant, and long-lasting, especially when compared to their high-speed steel (HSS) counterparts.

The two-flute design allows for a larger chip space, enhancing evacuation in softer materials while maintaining sharpness and precision. This makes the bits proper for contouring, 3D surface machining, slotting, and detailed finishing operations.

Common Usage Scenarios

1. Aerospace Component Manufacturing

In aerospace engineering, the demand for complex, high-precision components made from difficult-to-machine materials like titanium and Inconel is growing. 2-Flute Carbide Ball Nose End Mills Drill Bits are used extensively for profiling and surface finishing turbine blades, impellers, and structural components. The ball nose geometry allows smooth transitions between surfaces and reduces tool marks, which is crucial in maintaining aerodynamic efficiency.

2. Mold and Die Industry

The mold and die industry benefits greatly from the precision offered by 2-Flute Carbide Ball Nose End Mills Drill Bits. These tools are commonly used for finishing cavities, engravings, and 3D surface sculpting in tool steels and hardened materials. The ball nose enables machinists to create smooth contours and intricate features essential for plastic injection molds and stamping dies.

3. Medical Device Production

Medical device manufacturing requires ultraprecise machining, particularly when producing implants, surgical instruments, and orthopedic devices. 2-Flute Carbide Ball Nose End Mills Drill Bits are favored for their ability to achieve fine detail and tight tolerances on small and complex components, often made from stainless steel, titanium, or cobalt-chrome alloys.

4. Prototyping and 3D Contour Machining

In prototyping environments and design studios, the need for flexibility and precision is important. 2-Flute Carbide Ball Nose End Mills Drill Bits enable engineers and designers to mill intricate 3D shapes, curves, and prototype components in materials like aluminum, plastics, and composite boards. Their ball nose geometry makes them proper for creating smooth surface finishes directly from CAD models.

5. Automotive and Motorsport Applications

Within the automotive and motorsport sectors, these tools are vital in crafting performance parts and custom components. The 2-Flute Carbide Ball Nose End Mills Drill Bits allow for the machining of engine blocks, intake manifolds, and other complex parts where surface integrity and precision dictate performance.

Advantages Over Other Drill Bit Types

One of the key advantages of 2-Flute Carbide Ball Nose End Mills Drill Bits is their versatility in both roughing and finishing operations. While tools with more flutes are often used for high-feed operations, the two-flute configuration ensures better chip clearance, especially useful in softer metals and plastics.

The carbide construction also lends to prolonged tool life and reduced downtime, particularly important in automated production lines and high-volume manufacturing settings.

Additionally, the ball nose design reduces tool deflection and enables smoother transitions between cutting paths, reducing the need for secondary finishing operations.

Technological Developments and Coatings

Manufacturers of 2-Flute Carbide Ball Nose End Mills Drill Bits continue to innovate with advanced coatings such as TiAlN (Titanium Aluminum Nitride), DLC (Diamond-Like Carbon), and AlCrN (Aluminum Chromium Nitride). These coatings improve wear resistance, thermal stability, and enable higher cutting speeds without sacrificing tool integrity.

Some brands are now offering custom geometries and micro-sized 2-Flute Carbide Ball Nose End Mills Drill Bits designed for miniature components in electronics and microfluidics, marking another evolution in their application.

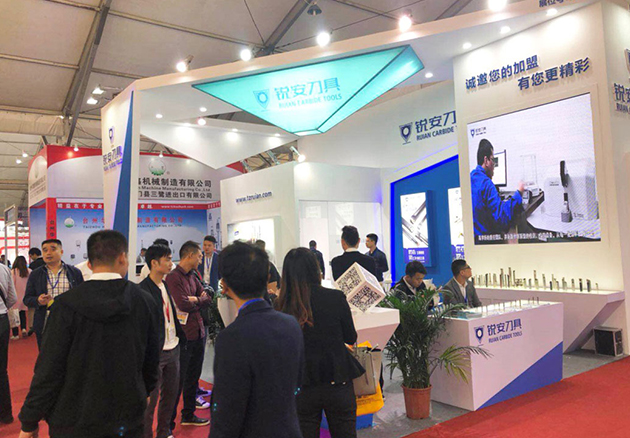

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China