RUIAN - An international inserts brand from customers

Home / News / Industry News / Negative General Stainless Steel Finishing Turning Inserts Gaining Momentum in Precision Machining Industry

RUIAN - An international inserts brand from customers

Home / News / Industry News / Negative General Stainless Steel Finishing Turning Inserts Gaining Momentum in Precision Machining Industry

In the rapidly evolving landscape of precision machining, Negative General Stainless Steel Finishing Turning Inserts are becoming indispensable tools for manufacturers seeking high-performance solutions in stainless steel finishing applications. As demand grows for components with good surface quality and dimensional accuracy, these specialized inserts are increasingly recognized for their reliability, durability, and cost-effectiveness in high-volume production environments.

Negative General Stainless Steel Finishing Turning Inserts are specifically designed to handle the challenges associated with machining stainless steels, which are notoriously difficult due to their work-hardening properties and tendency to generate excessive heat during cutting. These inserts feature a negative rake geometry that provides enhanced edge strength, making them well-suited for continuous cuts and demanding finishing operations.

One of the primary advantages of Negative General Stainless Steel Finishing Turning Inserts is their ability to maintain tool life under high cutting pressures. Traditional positive inserts can wear quickly or even chip when machining tough alloys, but the negative geometry distributes cutting forces more evenly across the insert. This not only improves longevity but also ensures a consistent surface finish — a critical requirement in sectors such as medical device manufacturing, food-grade equipment, and aerospace components.

In terms of usage scenarios, Negative General Stainless Steel Finishing Turning Inserts are increasingly employed in CNC lathe operations where precision is important. From valve components and pump housings to heat exchanger parts and turbine shafts, these inserts are used to produce tight tolerances and mirror-like finishes on complex stainless steel geometries. The inserts are also compatible with a variety of stainless steel grades, including austenitic, ferritic, and duplex types, further expanding their application scope.

Automotive manufacturers are another key adopter of Negative General Stainless Steel Finishing Turning Inserts. As more vehicles incorporate stainless steel in exhaust systems, structural elements, and fuel systems, the need for reliable machining solutions has grown. The inserts provide high-speed cutting capabilities without compromising on surface quality, making them proper for both roughing and finishing tasks in automated production lines.

In addition, these inserts are proving essential in the oil and gas industry, where corrosion-resistant alloys are a staple. Here, Negative General Stainless Steel Finishing Turning Inserts enable machinists to finish components such as valves, flanges, and couplings that must withstand pressure and corrosive environments. The inserts’ robustness under thermal and mechanical stress plays a key role in maintaining the integrity of such mission-critical parts.

Recent advancements in coating technologies have further enhanced the performance of Negative General Stainless Steel Finishing Turning Inserts. Modern inserts are often treated with multilayer PVD or CVD coatings that reduce friction, minimize built-up edge formation, and allow for higher cutting speeds. This means shorter cycle times, lower tooling costs, and improved overall process efficiency — outcomes highly valued in competitive manufacturing environments.

Machine shops focused on lean manufacturing and just-in-time (JIT) delivery systems have also found value in integrating Negative General Stainless Steel Finishing Turning Inserts into their workflows. The reduced need for tool changes and longer insert life translate to less downtime and greater throughput, directly supporting operational efficiency goals.

According to a recent market survey by ToolTech Insights, demand for Negative General Stainless Steel Finishing Turning Inserts has surged by 18% year-over-year, with the Asia-Pacific region showing particularly strong growth. This uptick is attributed to the expansion of stainless steel usage in industrial applications and the need for high-quality machining solutions in rapidly developing economies.

Despite their growing popularity, proper insert selection and application are critical to realizing the full benefits of Negative General Stainless Steel Finishing Turning Inserts. Factors such as feed rate, cutting speed, depth of cut, and coolant usage must be optimized based on the specific material and component design. changing cutting tool manufacturers are increasingly providing technical support, toolpath simulations, and digital twin solutions to help customers get the from these advanced inserts.

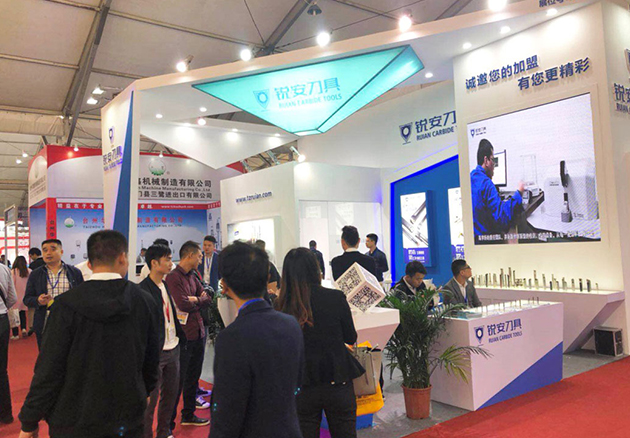

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China