RUIAN - An international inserts brand from customers

Home / News / Industry News / The Rising Demand for 4-Flute Flattened End Mills Solid Carbide Cutting Tools in General Machining

RUIAN - An international inserts brand from customers

Home / News / Industry News / The Rising Demand for 4-Flute Flattened End Mills Solid Carbide Cutting Tools in General Machining

The world of precision machining is witnessing a surge in the adoption of specialized cutting tools, and one of the prominent players in this field is the 4-Flute Flattened End Mills Solid Carbide Cutting Tools for General Machining. These versatile tools have become an essential component in a wide array of industrial applications, from automotive and aerospace to medical device manufacturing. Their unique design and good material properties enable them to outperform traditional tools, offering significant improvements in efficiency, precision, and longevity.

What Makes 4-Flute Flattened End Mills Solid Carbide Cutting Tools Stand Out?

4-Flute Flattened End Mills Solid Carbide Cutting Tools for General Machining are designed to tackle a variety of materials with enhanced efficiency. The four-flute design allows for faster material removal rates compared to two or three-flute end mills. This is especially important in high-production environments where speed and precision are important. The flattened geometry further improves the tool’s ability to maintain a stable cutting performance by reducing deflection and providing more consistent cutting forces.

The solid carbide material is another defining characteristic of these tools. Known for its hardness, wear resistance, and good thermal conductivity, solid carbide allows the tool to maintain sharp cutting edges for longer periods. This durability translates into lower tool replacement costs and reduced downtime, which is a critical factor in industries that rely on continuous production processes.

Key Applications of 4-Flute Flattened End Mills Solid Carbide Cutting Tools for General Machining

In general machining, 4-Flute Flattened End Mills Solid Carbide Cutting Tools are highly valued for their ability to handle a diverse range of tasks. One of the common applications is in milling operations for materials such as steel, stainless steel, aluminum, and high-temperature alloys. These tools can easily process complex geometries with tight tolerances, making them a good choice for industries like aerospace and automotive, where precision is critical.

For manufacturers of medical devices, 4-Flute Flattened End Mills Solid Carbide Cutting Tools are indispensable due to their ability to produce intricate features and smooth finishes on hard metals and biocompatible materials. The combination of strength and precision ensures that these tools can meet the rigorous demands of the medical sector, including the production of components such as surgical instruments and implantable devices.

The versatility of these tools also makes them highly suitable for mold-making, as they provide good results in both roughing and finishing operations. The ability to achieve fine finishes while maintaining high cutting speeds is an invaluable advantage in mold fabrication, where the precision and surface quality of the final product are crucial.

Advantages of Using 4-Flute Flattened End Mills Solid Carbide Cutting Tools

One of the main advantages of the 4-Flute Flattened End Mills Solid Carbide Cutting Tools for General Machining is their ability to balance cutting efficiency and tool longevity. The four-flute design facilitates a higher material removal rate, while the solid carbide composition ensures that the tool remains sharp over extended periods of use. This combination leads to increased productivity and reduced maintenance costs, a critical factor for manufacturers striving to meet tight production deadlines.

Furthermore, the tool's flattened geometry contributes to better chip evacuation, reducing the risk of clogging and improving overall cutting performance. Efficient chip removal is particularly important when working with tougher materials or at high speeds, as it reduces heat build-up and prevents tool wear.

Another key benefit is the good surface finish these tools produce. The increased cutting stability from the four-flute design ensures smoother cuts, which is particularly advantageous when working with materials that require a high degree of finish quality. The smooth finishes reduce the need for secondary processing, saving both time and resources.

Trends Driving the Growth of 4-Flute Flattened End Mills Solid Carbide Cutting Tools

Several key trends are contributing to the growing usage of 4-Flute Flattened End Mills Solid Carbide Cutting Tools for General Machining. One of the significant factors is the ongoing push for greater automation in manufacturing. As CNC machines and automated systems become more advanced, the demand for tools that can perform consistently at high speeds continues to grow. The 4-Flute Flattened End Mills Solid Carbide Cutting Tools are well-suited to this environment, providing the necessary performance and durability to support these technologies.

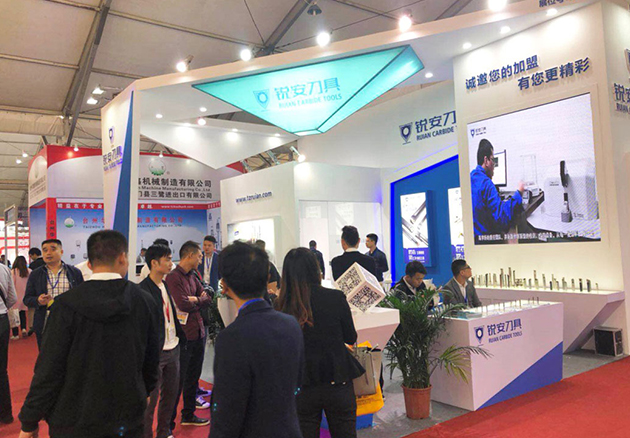

Taizhou City Ruian Cemented Carbides Tool Co., Ltd. is a National-Level High-Tech enterprise engaged in the research and development, production, and sales of CNC cutting tools and a National-Level "Specialized, Fineness, Featured and Innovative'Little Giant'" enterprise.

+86-576-81651888

+86-576-81651888

Apr 16,2019

TEL:

+86-576-81651888

TEL:

+86-576-81651888

FAX:

+86-576-86987998

FAX:

+86-576-86987998

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China

ADD:

No. 28, Xing'an Road, Chengxi Street, Wenling City, Taizhou City, Zhejiang Province, China